Introduction

In the bustling world of manufacturing, where efficiency is king and precision reigns supreme, the role of packaging machinery cannot be overstated. From streamlining operations to ensuring product safety, these advanced systems play a pivotal role in modern production facilities worldwide.

Automating the Packaging Process

Gone are the days of manual labor dominating the packaging floor. With the advent of cutting-edge technology, packaging equipment now boasts automation at its core. Automatic packaging machines, equipped with state-of-the-art features, have revolutionized the way goods are packaged. Whether it’s food products, consumer goods, or industrial components, these machines deliver unparalleled efficiency and consistency, reducing errors and speeding up production timelines.

Innovations Driving Efficiency

Packaging machinery manufacturers are at the forefront of innovation, continuously pushing the boundaries of what’s possible. From advanced filling machines to precision labeling machines, the industry is ripe with solutions designed to meet the diverse needs of manufacturers. By investing in cutting-edge technology, companies can streamline their operations, reduce waste, and stay ahead of the competition.

Meeting Industry Demands

As consumer preferences evolve and regulatory requirements become more stringent, the need for reliable packaging machinery suppliers becomes paramount. These suppliers not only provide cutting-edge equipment but also offer expertise and support to ensure seamless integration into existing workflows. Whether it’s sourcing spare parts or troubleshooting technical issues, partnering with a trusted supplier is essential for maintaining uptime and maximizing productivity.

Ensuring Product Integrity

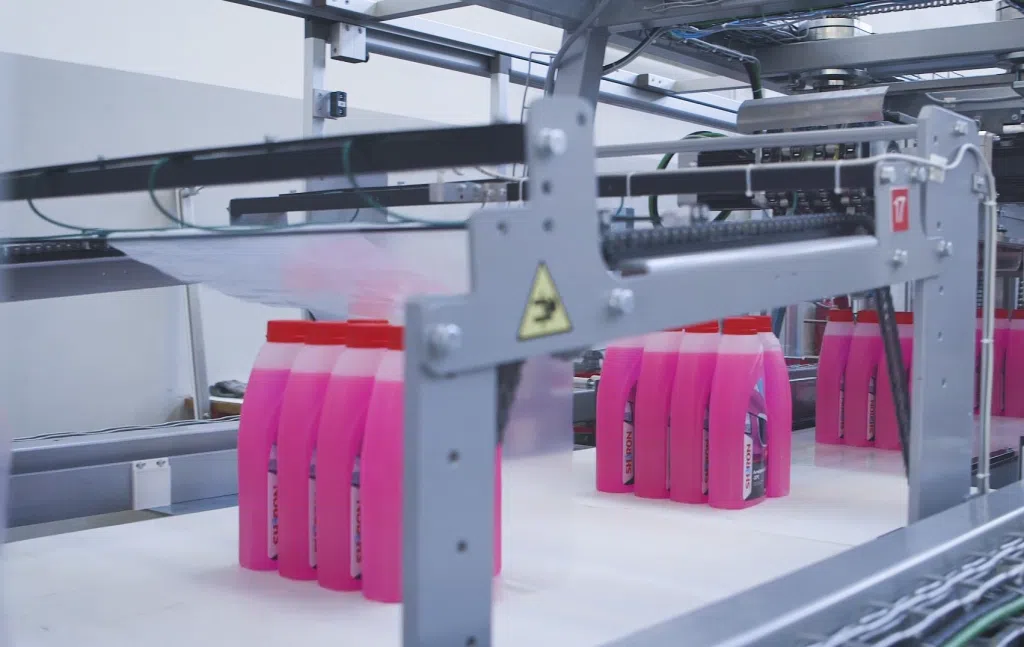

In industries where product safety is non-negotiable, sealing and shrink wrapping machines play a crucial role. These precision-engineered systems ensure that products are securely packaged, protecting them from contamination and damage during transit. By investing in robust sealing solutions, manufacturers can uphold their commitment to quality and customer satisfaction.

Optimizing Operations with Automation

In today’s fast-paced manufacturing environment, time is of the essence. That’s where packaging automation comes into play. By automating repetitive tasks such as cartoning and palletizing, companies can significantly increase throughput while reducing labor costs. This not only improves efficiency but also frees up resources to focus on higher-value activities, such as product development and innovation.

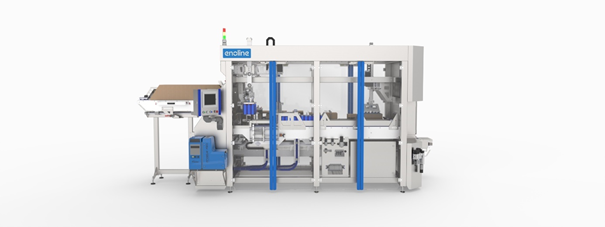

Enoline Solutions: Your Packaging Machinery Supplier in North America

Enoline is a leading supplier of packaging equipment in North America, offering a comprehensive range of solutions to meet industry needs. From automated packaging to maintenance services, Enoline is committed to providing quality products and outstanding support to its customers.

For more information about our products and services, visit our website at Enoline Solutions.

The Future of Packaging Machinery

As technology continues to evolve, so too will the field of packaging machinery. From AI-powered systems to smart packaging solutions, the possibilities are endless. By embracing these innovations, manufacturers can future-proof their operations and stay ahead of the curve in an ever-changing market landscape.

In conclusion, packaging machinery is the backbone of modern manufacturing. From automating processes to ensuring product integrity, these advanced systems play a vital role in driving efficiency, reliability, and innovation across industries. By investing in cutting-edge equipment and partnering with trusted suppliers, companies can unlock new levels of productivity and stay competitive in today’s dynamic marketplace.

Maintaining Peak Performance

Ensuring the longevity and optimal functionality of packaging machinery require diligent maintenance. From routine inspections to timely repairs, packaging machinery maintenance is essential for preventing breakdowns and minimizing downtime. Regular servicing not only extends the lifespan of equipment but also safeguards against costly repairs down the line.

Comprehensive Support Services

Packaging machinery suppliers offer a range of support services to keep operations running smoothly. From providing packaging machinery parts and service to offering technical assistance, these suppliers are committed to maximizing uptime and minimizing disruptions. By partnering with a reliable supplier, manufacturers can access the expertise and resources needed to overcome challenges and drive continuous improvement.

Meeting Diverse Needs

Every industry has its unique packaging requirements, and manufacturers must adapt accordingly. Whether it’s food packaging machinery for the food and beverage industry or industrial packaging machines for heavy-duty applications, versatility is key. Flexible packaging machinery can accommodate various product types, sizes, and materials, offering the agility needed to meet evolving consumer demands.

Driving Sustainable Solutions

In today’s eco-conscious world, sustainability is a top priority for many manufacturers. From reducing packaging waste to minimizing energy consumption, sustainable packaging solutions are in high demand. Flexible packaging machinery enables companies to adopt environmentally friendly practices by using recyclable materials and optimizing resource usage.

Looking Ahead

As the manufacturing landscape continues to evolve, so too will the field of packaging machinery. From advancements in automation to innovations in materials, the future promises exciting possibilities. By staying informed about emerging trends and investing in cutting-edge technology, manufacturers can stay ahead of the curve and thrive in a competitive market environment.

In summary, packaging machinery plays a vital role in modern manufacturing, driving efficiency, reliability, and innovation. By leveraging advanced technology, partnering with trusted suppliers, and embracing sustainable practices, manufacturers can optimize their operations and meet the diverse needs of today’s dynamic marketplace.

Conclusion

Packaging machinery stands as the backbone of modern manufacturing, propelling efficiency, reliability, and innovation to unprecedented heights. From automated systems to sustainable solutions, the industry continues to evolve, meeting the dynamic demands of diverse sectors worldwide.

As companies strive for operational excellence, the role of packaging equipment becomes increasingly vital. From automating processes to ensuring product integrity, these advanced systems play a pivotal role in driving productivity and profitability.

In this ever-changing landscape, partnering with a trusted supplier like Enoline Solutions is essential. With a commitment to quality, innovation, and customer satisfaction, Enoline offers a comprehensive range of packaging solutions tailored to meet the unique needs of businesses in North America.

Looking ahead, the future of packaging machinery is bright, with advancements in technology promising even greater efficiency, reliability, and sustainability. By staying informed, embracing innovation, and partnering with trusted suppliers, manufacturers can navigate the complexities of the modern marketplace and emerge stronger than ever before.

FAQs (Frequently Asked Questions)

- How often should packaging machinery be serviced? Regular servicing is recommended to maintain optimal performance. Depending on usage, quarterly or semi-annual maintenance schedules are common.

- Are packaging machinery parts interchangeable between manufacturers? While some components may be compatible, it’s best to consult with the original equipment manufacturer for precise replacements.

- Can packaging machinery be customized for specific applications? Yes, many manufacturers offer customization options to tailor packaging machinery to unique product requirements and production environments.

- What are the benefits of investing in automated packaging solutions? Automated packaging solutions offer increased efficiency, reduced labor costs, and enhanced product consistency, resulting in higher overall productivity.

- How can I troubleshoot common issues with packaging machinery? Referencing the equipment manual and consulting with technical support are recommended steps for troubleshooting common issues with packaging machinery.

- Is training provided for operating packaging machinery? Yes, manufacturers typically offer training programs for operators to ensure safe and efficient usage of packaging machinery.

In conclusion, packaging machinery is the cornerstone of modern manufacturing, driving efficiency, reliability, and innovation across industries. By embracing cutting-edge technology, partnering with trusted suppliers, and prioritizing sustainability, businesses can unlock new levels of success in today’s dynamic marketplace.